The awareness also of the chemical industry that within a few decades fossil fuels will be exhausted has led companies to study manufacturing systems for non-polluting, biodegradable and sustainable products. Moreover, it is now well established that the economic advantage also comes from not having to dispose of waste, which is very expensive for companies.

The term Green Chemistry has been defined by IUPAC and EPA (the US Environmental Protection Agency) as “the invention, design and use of chemicals and processes to reduce or eliminate the use and production of hazardous substances”.

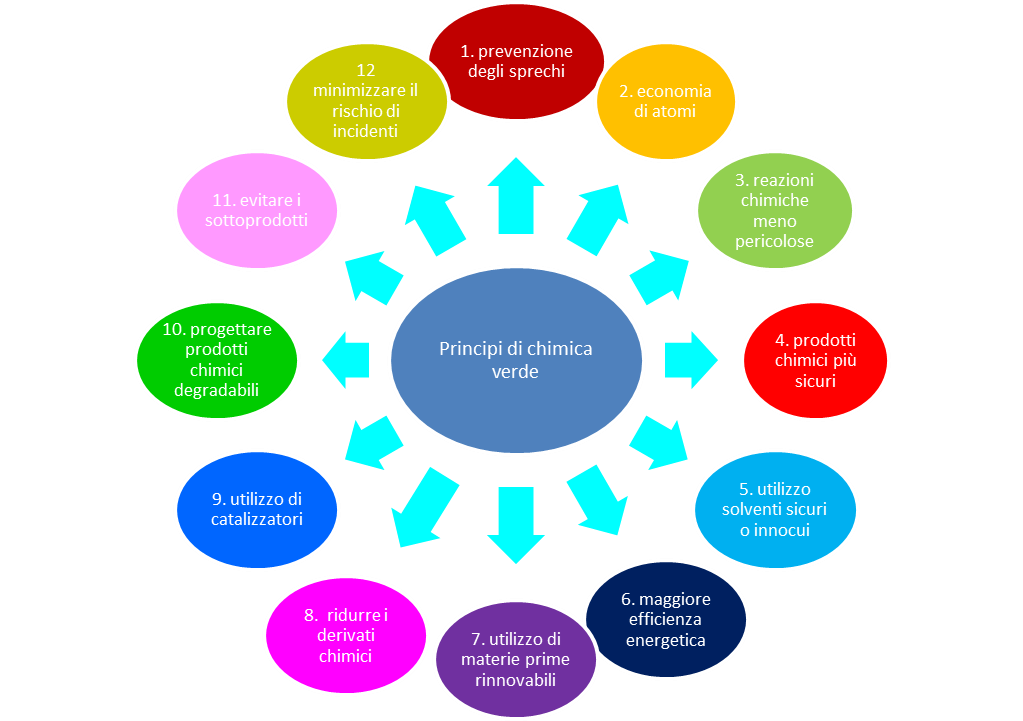

The EPA’s programme is based on 12 fundamental principles:

1. Prevent waste by designing appropriate chemical syntheses.

2. Design the syntheses so that the final product contains the maximum proportion of the starting materials.

3. Design syntheses that use and generate substances with minimal environmental toxicity.

4. Design products that are safer from the point of view of environmental impact.

5. Use safer solvents / reaction conditions or harmless substances.

6. Increase energy efficiency by trying to perform reactions at room temperature and pressure.

7. Use renewable raw materials such as agricultural products or waste from other processes.

8. Avoid chemical derivatives.

9. Use catalysts because they allow a single reaction to be made several times.

10. Design chemicals and products that degrade after use.

11. Monitor and control the synthesis in real time to minimize or eliminate the formation of by-products.

12. Design chemical products to minimise the potential for chemical accidents including explosions, fires and environmental releases.

The Three R’s policy of Reducing, Reusing and Recycling helps to reduce the amount of personal waste we throw away. Such waste also includes hazardous household products that contain corrosive, toxic, flammable or reactive ingredients that may pollute the environment and represent a threat to our health. Moreover, almost all industrial processes, from the production of consumer goods to the production of energy, generate, in addition to the final product, variable types and quantities of waste materials that we can use. As with urban solid waste, such as cardboard, newspapers and beverage containers, these industrial materials are also valuable assets that can be reduced, reused and recycled. For example, 80% of all industrial oils used in production processes are prematurely and often improperly eliminated. And luckily, chemical engineers are actively involved in developing ways to increase life through fundamental chemical steps that minimise the ageing process.

Experts are also actively engaged in changing the mindset of industries so that they consider the value of a used-up material as a product or as a commodity and not as waste.