Cigarettes are made up by a burnt part – which contains nicotine, heavy metals, tar and other substances that are dangerous for our lungs health without being excessively harmful for the environment that absorbs them – and by filters based on cellulose acetate, a plastic which takes more than ten years to decompose. Discover the chemistry of cellulose acetate in exercise 38.

In 2020 Legambiente monitored 189000 m2 of beaches as part of the Beach Litter survey, studying the incidence of various types of abandoned waste. The numbers of this research are frightening: an average of 654 item of waste per 100 m2 has been calculated. In a ranking of waste varieties, cigarette butts are at the top (together with plastic fragments) representing 14% of the total, that is, there are on average 90 butts per 100 m2. It is estimated that in the world, 4.5 trillion butts are left on the ground; in Italy 13000 tons are produced.

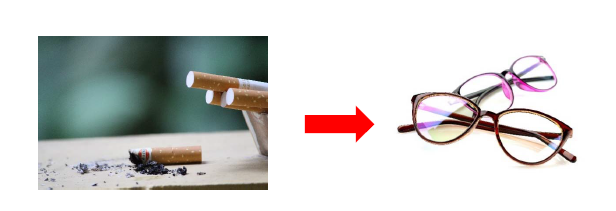

Several Italian start-ups face this issue by transforming cigarette butts into a resource, that is, by recovering the cellulose acetate of the filters using it in prestigious products such as eyewear and constructions finishes. The CNR Institute on Air Pollution, as part of the RINASCE Project, has also studied solutions to give cigarette butts another life. They designed a system to quickly separate different components, remove contaminants and then recover the most valuable product fractions.

The filter treatment process consists of four phases:

1. separation of acetate from paper, tobacco and tar so that the product is not harmful;

2. washing treatment to eliminate harmful substances: the impure water is collected and sent to a purification system;

3. drying up;

4. processing of the material through a thermal process.

Regenerated cellulose acetate can be reused in the production of objects, using most of the plastic processing methods on the market, from fashion to accessories. In particular, the butts have been transformed into spectacle frames, although the process still needs to be improved in yield: to produce a pair of glasses are now needed 1000 butts, equal to what produced in a month by two average smokers.

Another project has recently being developed in order to obtain cellulose fibre to produce surgical masks from cellulose acetate of cigarette butts: the fibre contained in the cigarette filters is sanitized and then transformed into a soft fabric such as cotton through a treatment similar to wool carding. In the time of Covid-19 this project has great importance as the fabric can be washed and reused, with a lower environmental impact on waste.

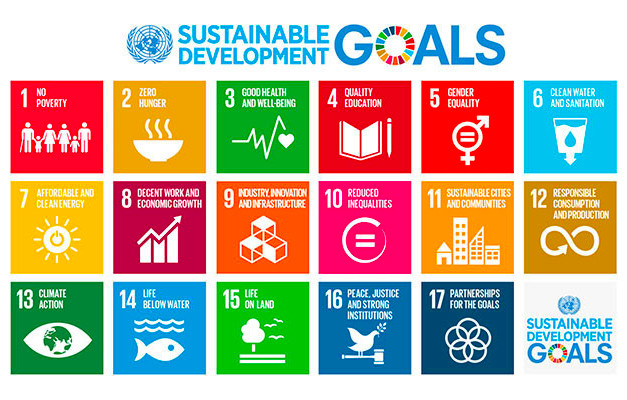

ACTIVITY: The subject of this page recalls two goals of the 2030 Agenda. The first one is n. 12; which is the other one? Which are the goals to reach according to both of them?