Vanilla-flavoured ice cream made from plastic bottles? It is not science fiction but a recent reality after the discovery that it is possible to convert plastic waste into vanillin flavour through the action of genetically modified bacteria.

Vanillin is a natural aromatic substance that is traditionally extracted from the pods of the vanilla plant, vanilla plantifoglia of the Orchideaceae family, and to which it imparts its characteristic aroma.

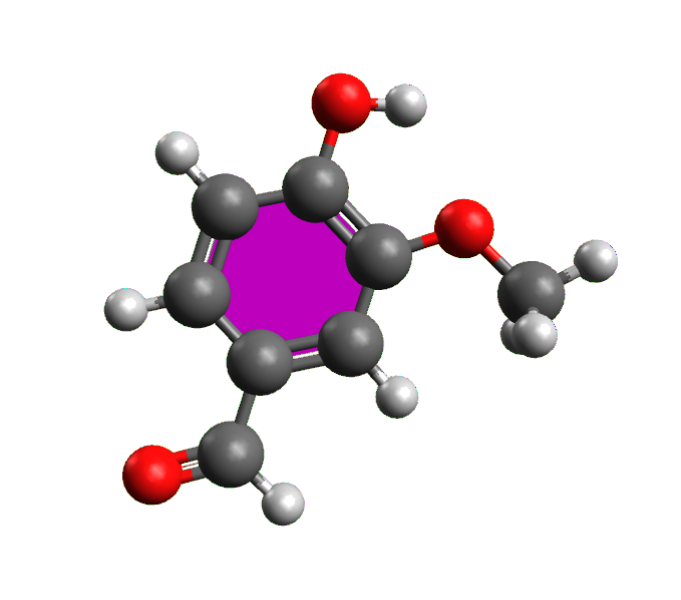

Chemically, vanillin is a member of the aldehydes class of organic compounds. Specifically, it is 4-hydroxy-3-methoxybenzaldehyde whose general formula is C8H8O3. Used mainly as a flavouring in the confectionery industry and also added to some varieties of chocolate, it is also used in the perfume industry as one of the substances whose fragrance is most persistent.

Natural vanillin is cultivated in tropical areas and Madagascar is currently the world’s largest producer. However, as the demand for vanilla flavouring far exceeds the production of the pods, which undergo lengthy and expensive processing, the vanillin used in confectionery and perfumery is of synthetic origin. Whereas world production of natural vanillin is estimated at around 40 tonnes per year, synthetic vanillin amounts to around 12 000 tonnes per year.

Synthetic vanillin is obtained by the oxidation of eugenol, a substance found in clove oil, with potassium permanganate or ozone, or by the reaction of guaiacol (do exercise 44), a substance obtained from the fractional distillation of beech or pine tar, with formaldehyde; otherwise, it can be synthesised from lignin, from which it is extracted, after several treatments, from the waste water of paper mills.

Since the PET from which plastic bottles are made has a chemical composition very similar to the vanillin molecule, two researchers from the University of Edinburgh in Scotland have discovered that it is possible to convert plastic waste into vanilla flavour through the action of genetically modified bacteria.

Once the decomposition of polyethylene terephthalate (PET) (do exercise 27) into its basic unit terephthalic acid is achieved, it is mixed with engineered Escherichia coli bacteria and kept for one day at 37 °C, resulting in a yield of approximately 79% vanillin. Although this is already a very good result, scientists are working on obtaining even more efficient bacteria in order to obtain more vanillin from plastic and not only fibres for textiles, the ultimate products of bottle recycling. Indeed, one million plastic bottles are sold every minute in the world, of which only 14% are recycled.

The discovery, besides offering a new source of vanillin production, is an excellent example of virtuous waste recycling: plastic, instead of being dispersed in the environment or accumulated, constituting a cost, becomes a resource and a source of income, within a circular economy.

ACTIVITY: Vanillin also has an application in chemical laboratories: it is used in thin-layer chromatography. Learn more about this technique and, in particular, the role vanillin plays.